- Evaluate axial and sagittal spatial resolution in preclinical and industrial micro-CT

- Provides high resolution contrast

- Bar and point structures down to 5 microns (air, QRM-70113 and resin, QRM-70114) or to 1 micron (NANO, QRM-70119)

- Corresponds to 3.3 to 100 lp /mm (air, QRM-70113 and resin, QRM-70114) or 500 to 50 lp/mm (NANO, QRM-70119)

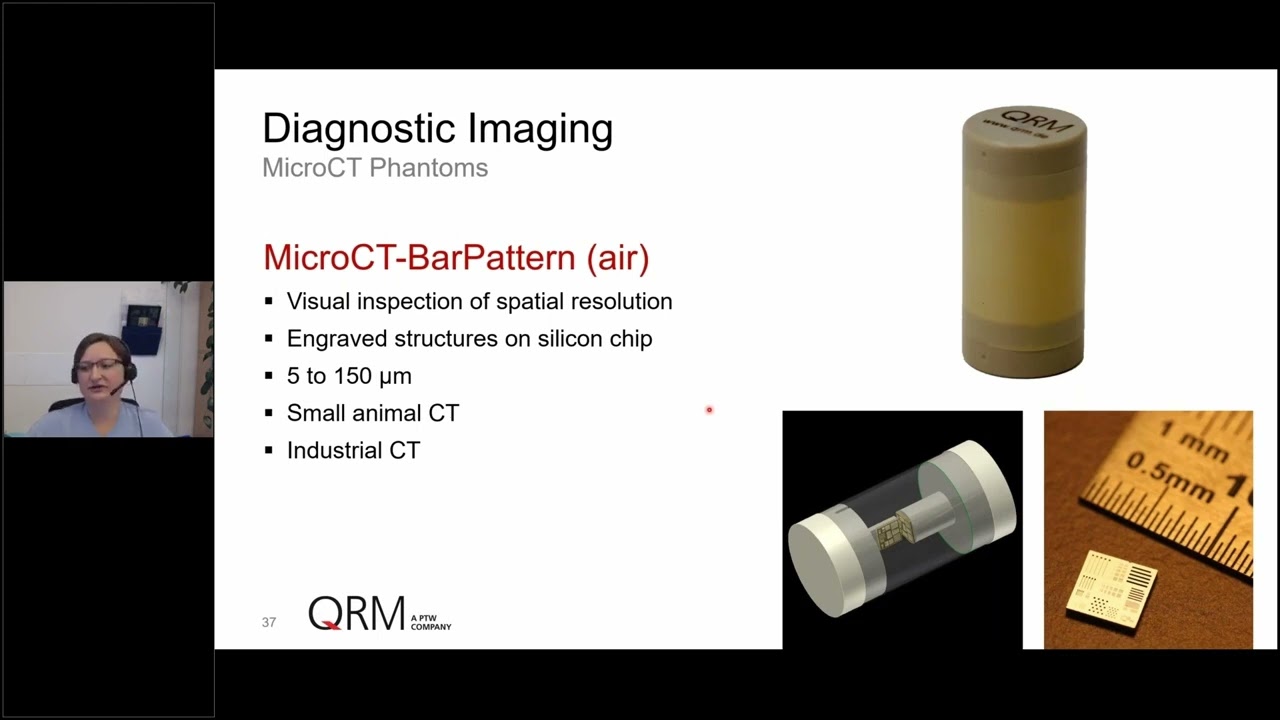

The Micro-CT Bar Pattern Phantoms are used to assess the spatial resolution in micro-CT in a direct visual manner. The phantoms offer an alternative to indirect methods for the evaluation of spatial resolution in high-resolution X-ray imaging modalities.

The phantoms contain of two chips, one orientated axial and one oriented in perpendicular (sagittal) to it. The chips are mounted on a slim support in air (QRM-70113, QRM-70119) or embedded within a resin cylinder (QRM-70114). The optimized arrangement of the different bar and point structures allows for the evaluation of spatial resolution in the center as well as in the periphery of the image in one single measurement.

QRM-70113, QRM-70114: The 5 mm x 5 mm chips contain bar and point patterns ranging from 5 to 150 microns (i.e. 100 to 3.3 lp / mm). The depth of the structures varies between 70 and 150 microns.

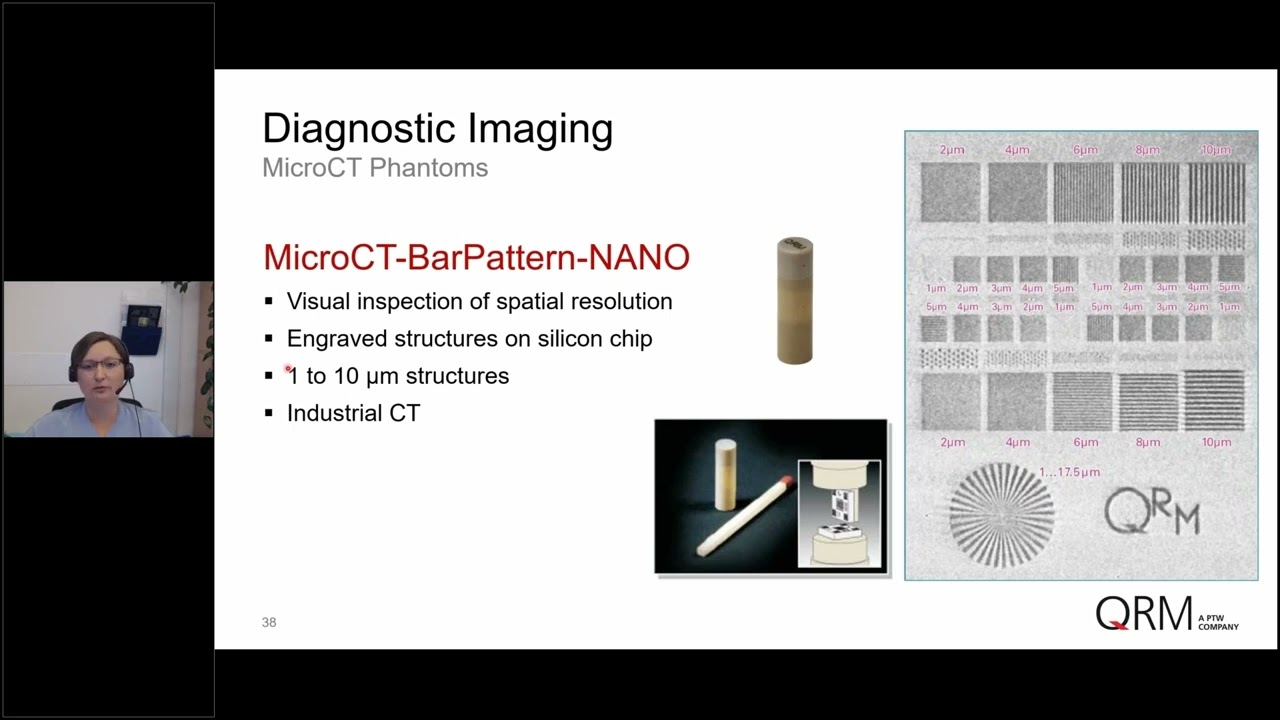

QRM-70119: The 3 mm x 3 mm chips contain bar and point patterns ranging from 1 to 10 microns (i.e. 500 to 50 lp / mm). The depth of the structures varies between 5 and 15 microns. In addition, a slanted edge and a so-called Siemens-star (actinomorphic star) are placed on the chip.

Other dimensions of housing are available upon request.